-

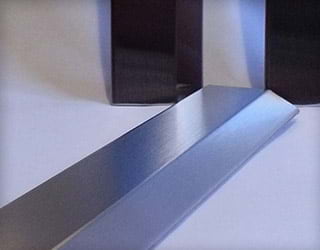

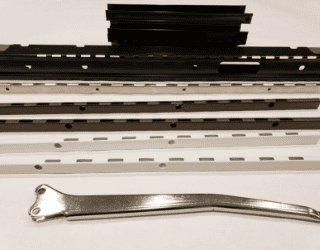

Custom Roll Forming

Custom Roll Forming

Learn MoreAt Premier Products of Racine, we are ready and able to be your complete custom roll forming resource. Our well-maintained, 210,000 square foot facility houses 9 roll forming mills that enable us to manufacture top quality parts measuring from .010″ to 3/16″ thick, up to 20″ wide, and in unlimited lengths. We maintain precision cross-sectional tolerances of ±.003″, angular dimensional tolerances of ±.25° or better, with straightness and twist both accurate to less than ±.015″.

-

Custom Metal Stamping

Custom Metal Stamping

Learn MorePremier Products of Racine enjoys a reputation for producing superior quality custom metal stampings. We are knowledgeable, competitive, and can accommodate the most demanding requirements for a wide variety of industries. With our expertise in many types of stamping methods including progressive stampings, coining, continuous strip, as well as compound die techniques, we can offer a well-priced solution tailored for your specific needs.

-

Custom Sheet Metal Fabrication

Custom Sheet Metal Fabrication

Learn MoreAt Premier Products of Racine, we offer a full spectrum of custom metal fabrication services, including bending, forming, punching, rolling, shearing, as well as welding and assembly. Our facility is equipped to tackle jobs ranging from single prototype pieces all the way to high volume production runs. Quick-change tooling capabilities, along with highly automated robotic loaders and un-loaders, allow us to rapidly produce parts from steel, stainless, aluminum, copper, and challenging high strength alloys.

-

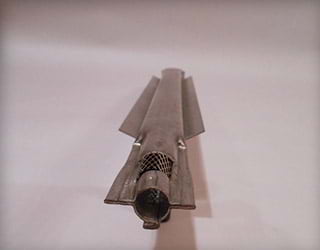

Projection Welding

Projection Welding

Learn MorePremier Products of Racine has recently added projection welding to our capabilities. Our machines are capable of high to low volume projection and spot welding. With sophisticated controls we are able to do multiple welds in the same operation allowing us to customize the weld depending on the materials, parts and geometries.

-

Assembly

Assembly

Learn MoreLet Premier Products turn your assembly problems into solutions. We understand that producing a part is only one aspect of a finished product. Many applications require assembly of multiple components using a variety of techniques including welding, riveting, rivnut insertion, fastening, clinch-lock, manual attachment, and adhesive bonding. Whether it is low volume manual operations or high volume automated systems we have the ability to meet your needs.

-

Finishing

Finishing

Learn MorePremier Products of Racine is familiar with all different kinds of secondary finishing techniques including powder coat, e-coat, plating, black oxide treatment, annealing, vibro deburring, anodizing, enameling, and polishing. If there isn’t a service we offer directly, we have highly qualified vendors that are capable of any custom finishing you require. Our aim is to bring your product to life by providing you with a completed and finished part.

ABOUT US

Over 25 Years of Outstanding Service

Premier Products of Racine provides custom roll formed products to a variety of industries and applications, including office furniture, barbeque, appliance and tanker. Established in 1999, Premier is a full service company that provides quality products at very competitive prices.

GET IN TOUCH TODAY